Non-destructive testing

of welds and joints

Non-destructive testing of welds and metals, without compromising components.

We offer NDT (non-destructive testing) services to verify the integrity of welds, welded joints, and metallic materials—either on-site at your workshop or at our facility.

We use reliable techniques, carried out by certified technicians, with fast and accurate reports.

A solution designed for fabrication shops aiming to improve the quality of the finished product without slowing down production.

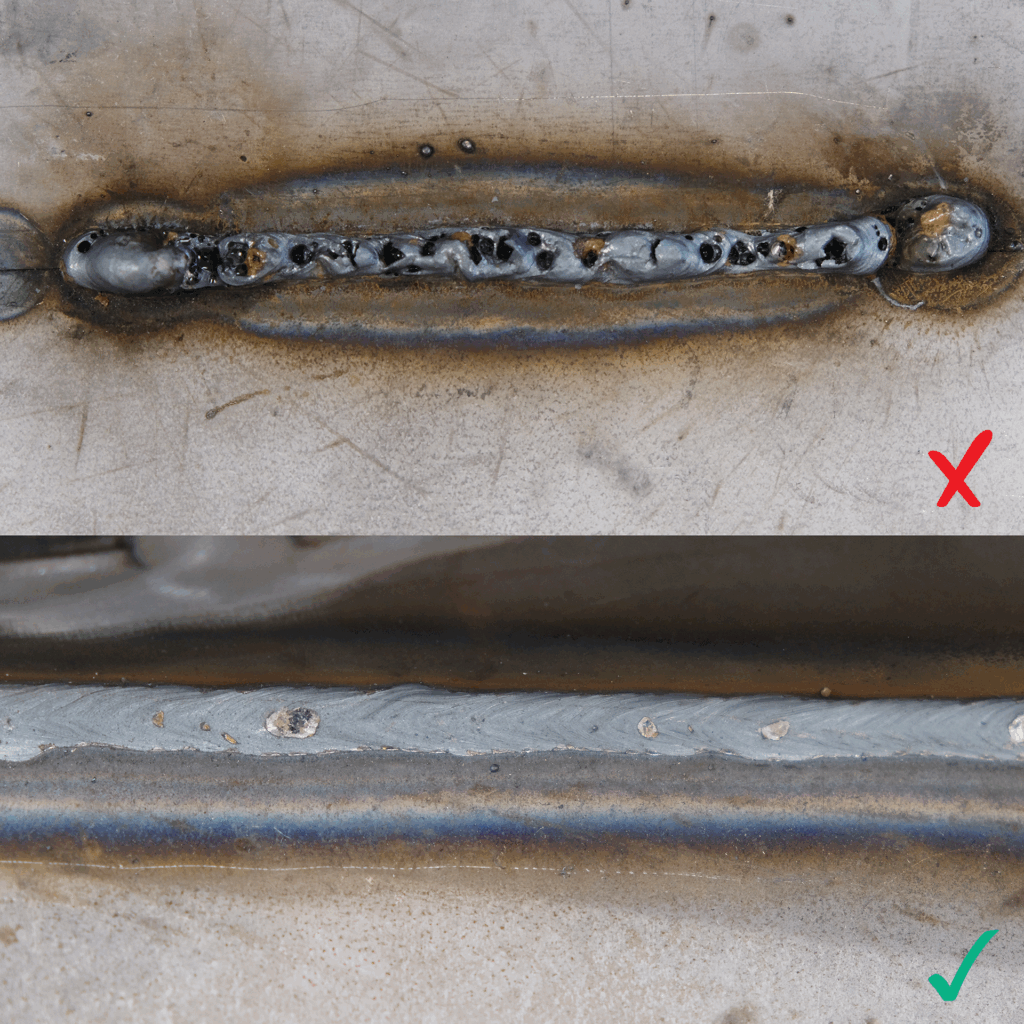

This weld is clearly defective.

But not all flaws are so easy to spot.

Many hide inside the part, between layers, or in hard-to-reach areas.

With non-destructive testing (NDT), we can detect cracks, porosity, and inclusions invisible to the naked eye—before they become a risk for the component or for the person using it.

Tools and methods for non-destructive testing

Metallic materials

✔ Carbon steel

✔ Stainless steel

✔ Aluminium

✔ Nickel alloys

Components and processes

✔ TIG, MIG, and multipass welds

✔ Castings, forgings, and machined parts

✔ Tanks, basins, and ducts (non-PED)

NDT techniques we use

To ensure process reliability and prevent hidden defects, we apply three specific methods, selected based on the type of component, material, and function.

Leak testing (non-PED)

Specifically designed to verify the tightness of tanks and containers not subject to PED regulations, using penetrant liquids.

Visual Testing (VT)

Used to inspect welds and visible surfaces. Allows the detection of both obvious and microscopic defects.

Penetrant Testing (PT)

A high-sensitivity technique for detecting cracks, porosity, or lack of fusion—ideal for stainless steel, aluminium, and visible welds.